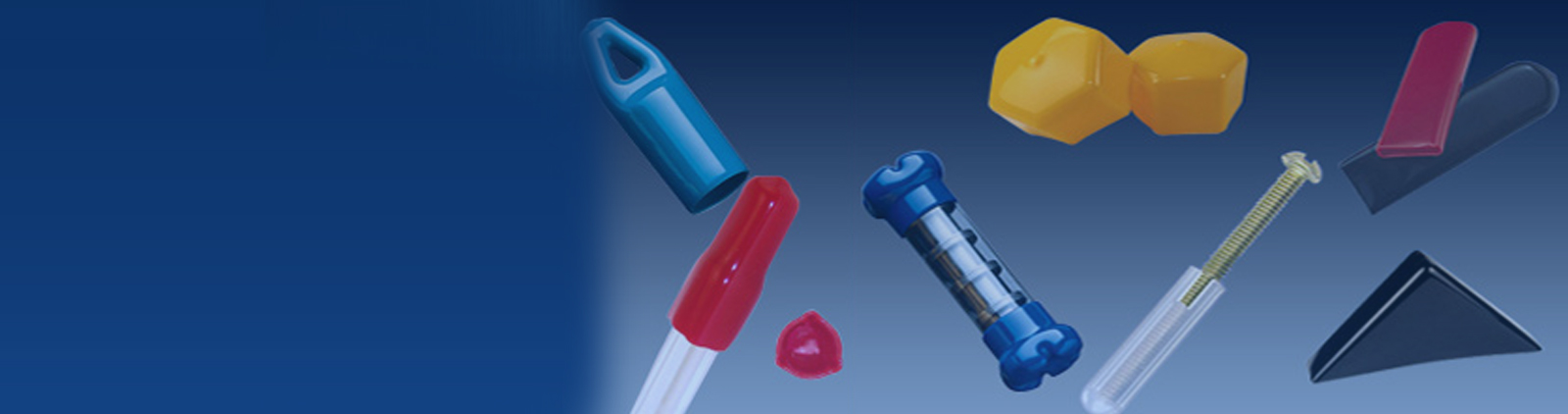

Manufacturer and exporter of dip moulded PVC plastisol for various applications.

We offer best quality PVC Plastisols that can be compounded in almost any hardness, clarity, and color and can be pumped or sprayed. The surface appearance of PVC Plastisol can go from shiny to matte to foam. Some excellent features of dip moulded PVC plastisol:

- USP Class VI materials for medical products

- Glossy or matte finishes

- Available in both custom and standard colors including fluorescent colors

- Available at economical rates

- Available from a minimum thickness of 0.005 inches

- Soft like skin or hard like glass

- Can to elongated up to 500%

- Weather resistance, electrical insulation, fire resistance, abrasion resistance are the other features.

High Quality Dip Moulded PVC Plastisol

The Dip moulded Plastisols including CMYK Process Inks PVC Plastisol, Automobile Ancillary, PVC Plastisol Coatings, PVC Compound Plastisol exhibit quality craftsmanship and the tooling costs get more reasonable with dip moulded PVC plastisol. The fabrication department enables fast turnaround and Enhances appearance and function with a non-slip cushioned feel. The Plastisol coating renders a consistency and a high-quality dip coating that ensures no area of the surface is compromised.

Plastisol PVC Dip Coating

Plastisol PVC dip coating is a popular type of protective finish used for a variety of products. Unlike other coating methods, dip coating does not require secondary finishing. This is due to the relatively low labor costs of this process. In addition, the dip coating process produces minimal waste since only the required amount of plastisol is used. The benefits of dip coating include lower manufacturing costs, reduced material waste, and easy handling.

CMYK Process Inks PVC Plastisol

Plastisol Inks

Automobile Ancillary

PVC Dip Coating Plastiso

PVC Plastisol Coatings

PVC Compound Plastisol

Dip Moulded PVC Plastisol products are used in following industries